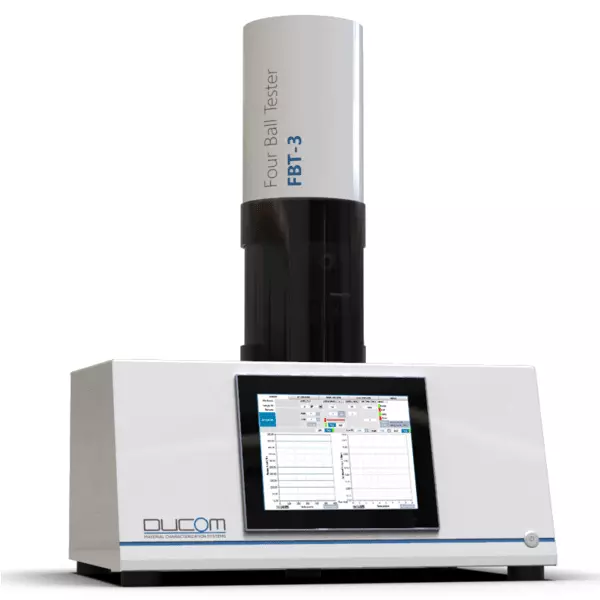

Automated Benchtop Four Ball Tester FBT-3

Ducom Automated Four Ball Tester FBT-3

Methods: ASTM D2266, ASTM D2596,ASTM D2783,ASTM D4172,ASTM D5183,DIN 51350-2, DIN 51350-3, DIN 51350-4, DIN 51350-5, IP 239, ISO 20623:2017, Add-on KRL SST Module – CEC L45-99

- Automated Robust benchtop four ball tester

- Extreme Pressure (EP) Tests

- Wear Preventive (WP) Tests

- Coefficient of Friction (COF) Tests

- A patented friction measurement system

- Automated scar prediction system option

- FBT-3, the 1st automated compact four-ball tester with preloaded protocols.

- Optional add-on modules of KRL SST and HT

- Automatic Loading

- Built-In Touch Screen Interface

- Custom test program mode

- Up to 15 EP test per hour

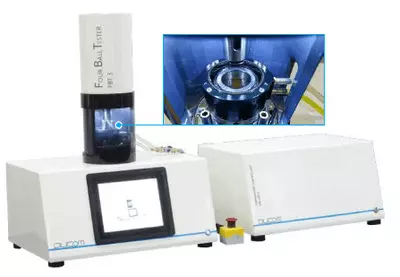

The Ducom Automatic Benchtop four-ball tester FBT-3 is the most dependable instrument for evaluating lubricants’ wear prevention, extreme pressure, and frictional characteristics. Advanced automation capabilities of FBT-3 make the four-ball test effortless and precise.

With patented friction measurement system, automated scar prediction system, and other cutting-edge features enhance the accuracy and convenience of four-ball testing.

TOUCHSCREEN INTERFACE AND DATA ACQUISITION

The IP65-rated touchscreen interface and cutting-edge data acquisition hardware combination enable FBT-3 to handle even the most challenging testing applications.

Designed for full-touch compatibility, pre-configured test protocols allow users with minimal training to set up ASTM and other standard tests easily. Custom test protocols can be set when the needs exceed the scope of standard test procedures.

SMART AND COMPACT FOUR BALL TESTER

FBT-3 is an exceptional benchtop four-ball tester meticulously engineered to serve as the backbone of lubricant laboratories. With its compact dimensions measuring 40 x 60 x 85 cm, this robust four-ball tester sets the stage for characterizing the properties of lubricants.

- The wear preventive (WP)

- Extreme pressure (EP)

The pneumatic chambers, pistons, and load sensors seamlessly collaborate to achieve precise user-defined load controls. The automated loading greatly enhances the determination of load wear index and incipient seizure load. FBT-3 automatic four-ball tester boasts a simplified test setup and an intuitive software interface that enable up to 15 EP tests per hour effortlessly. The touch compatibility of the control and data acquisition system ensures a seamless user experience.

- The FBT-3 uses a pneumatic system to apply precise load to the test balls. This ensures that the friction force measurements are accurate and repeatable.

- The FBT-3 uses a high-precision sensor to measure the friction force. This sensor detects even the slightest changes in friction, which is essential for meeting the demanding requirements of modern lubricant quality standards.

- The FBT-3 is a state-of-the-art compact four-ball tester that provides the most accurate and reliable friction force measurement. FBT-3 is the ideal choice for lubricant manufacturers and testing laboratories that need to meet the highest quality standards.

ASTM, DIN, IP COMPLIANT

Ducom FBT-3 is a cutting-edge four-ball tester with a maximum load capacity of 12000 N, a top speed of 3000 rpm and can reach maximum temperatures up to 200 °C. FBT-3 benchtop four-ball tester stands ready to tackle any challenge.

Compliant with ASTM, DIN, and IP standards, the FBT-3 ensures accurate and reliable characterization of wear preventive (WP) and extreme pressure (EP) properties of lubricants.

ASTM conducts the Proficiency Testing Program (PTP) to assess data reproducibility in tribology labs. The Ducom Four Ball Tester (FBT-3) is globally benchmarked in the ASTM PTP study for friction and wear tests of lubricants. The PTP assessment includes Test Performance Index (TPI) and Z-score to measure lab performance and data reproducibility.

STATE-OF-THE-ART PATENTED TECHNOLOGY

Patented friction force measurement technology for unparalleled measurement accuracy. Rapidly increasing lubricant quality standards demand the use of more sensitive measurement techniques to evaluate lubricants.

FBT-3 Four ball tester uses patented friction force measurement technology to provide unparallel measurement accuracy.

THERMAL MANAGEMENT UNIT

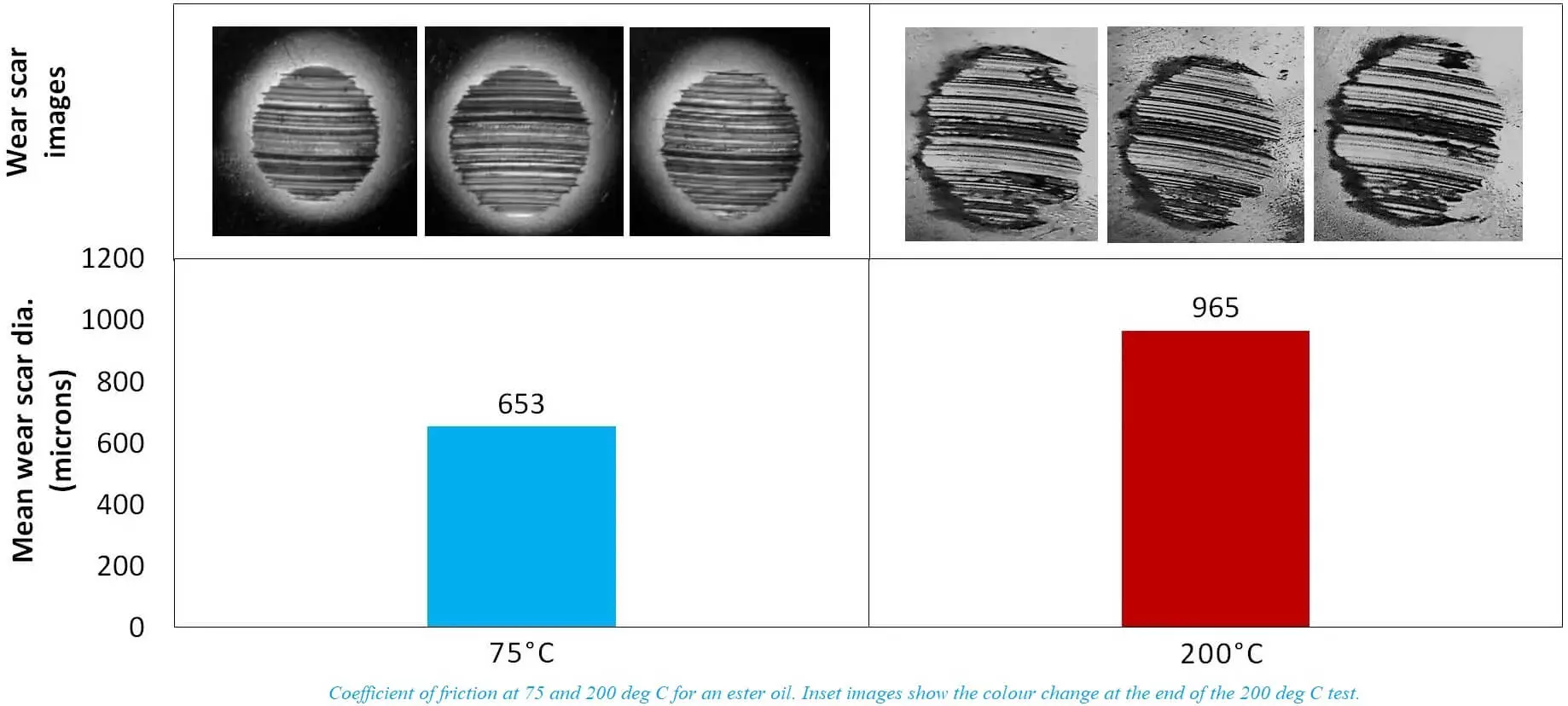

The Arrhenius rate demonstrates a 10 to 20°C rise in temperature can significantly reduce the life of oil by half. FBT-3 at 200°C becomes incredibly valuable when it comes to evaluating high-performance additives intended to enhance oil lifespan.

Groundbreaking development in the realm of FBT-3, specifically tailored to address the challenges posed by oils and grease within critical machine elements operating at temperatures surpassing 200°C.

FBT-3 delivers a multitude of customer-perceived benefits while maintaining compatibility with legacy data in laboratories.

FBT-3 with a 200 deg C heating unit can maintain a stable temperature and load as per standard test conditions. The advanced thermal management system protects the critical components in the FBT-3, which results in low maintenance and service cost for the customers.

FBT-3 represents a significant advancement in the formulation of lubricants for critical machine elements operating under high-temperature conditions, whether at 200°C or an even more extreme 450°C.

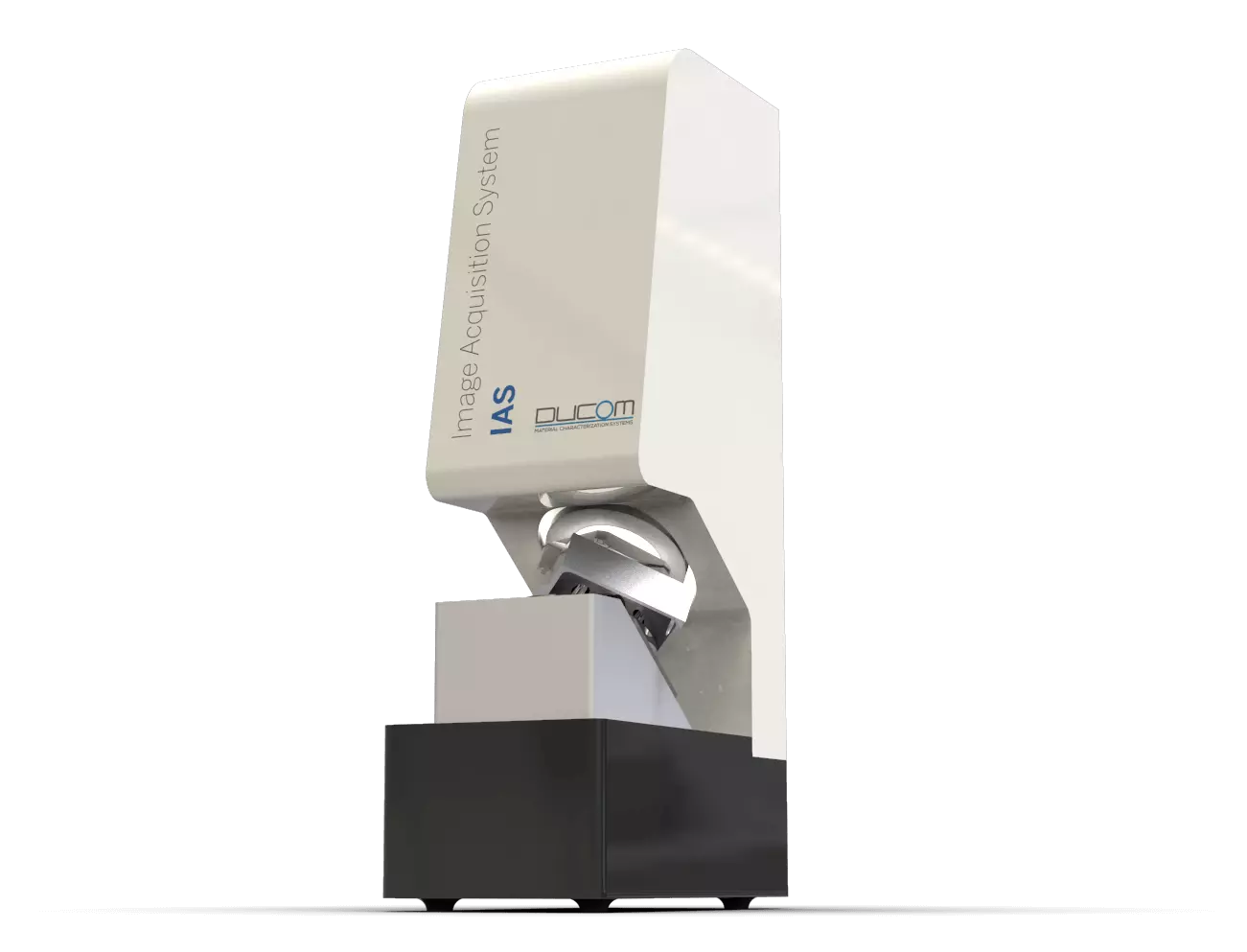

DIGITAL IMAGE ACQUISITION SYSTEM (IAS)

DIGITAL IMAGE ACQUISITION SYSTEM (IAS)

The Digital Image Acquisition System (IAS) eliminates the need to remove individual balls from the ball pot, using a trial-and-error method to focus and measure the ball-wear scar. The system includes a camera, optics, lighting, and software and can hold the entire ball pot after EP and WP tests.

Some systems offer smart scar measurement technology, which aids in calculating wear scar area and enhances measurement accuracy.

| Test Methods | ASTM D2783, D4172, D2266, D5706, D2596, ASTM D5183, ISO 12156-1, IP 239, IP 300, DIN 51350-2, DIN 51350-3: DIN 51350-4; DIN 51350-5; ISO 20623:2017 |

| Test Parameters | Wear Preventive (WP) Tests, Extreme Pressure (EP) Tests Coefficient of Friction (COF) Tests, Custom test program mode. Pre-loaded test protocols |

| Data Output | Digital display of load, time, and temperature;Friction coefficient, Wear scar diameter, Load carrying capacity, Weld point, extreme pressure properties, and seizure load Data acquisition and analysis software with IAS System |

| Data Acquisition | Software for data acquisition and analysis with integrated PC and USB port. |

| Ease of Use | Easy to use touch screen interface; Automatic data acquisition; User-friendly software, easy sample loading |

| Versatility | Measures wear resistance and extreme pressure performance of lubricants and additives. Suitable for different lubricants, fluids, and greases |

| Accuracy | Patented friction force measurement technology for unparalleled measurement accuracy and digital data acquisition |

| Load capacity | 1080 Kg |

| Friction Force | 0 to 200 N |

| Loading Sequences | Constant load test, incremental loading, and stepwise loading |

| Test Load Control | Automatic computer controlled pneumatic loading |

| Speed range | 100-3000 RPM |

| Temperature range | Ambient to 120°C |

| Temperature Control | Integrated temperature control module with temperature sensor inside the ball pot |

| image acquisition system | Automated CCD camera, less time to measure wear scar. Entire ball pot can be housed |

| Sample holders | Interchangeable sample holders for various sample sizes |

| Software | User-friendly software for data acquisition, analysis, and reporting |

| Compact bench top unit | Yes |

| Dimensions | 60 x 40 x 80cm |

| Weight | 114 kg |

| Power requirements | 220V AC, 50/60 Hz |

| Compliance | ASTM, DIN, ISO, IP,JIS standards |

- KRL Shear Stability Test Attachment (CEC L-45, DIN 51350-6)

- High-Temperature Test Attachment (ambient to 200 °C)

- MOOHA – Digital Lab Assistant (Software)

- AI Wear Scar Prediction and Materials Library (Software)

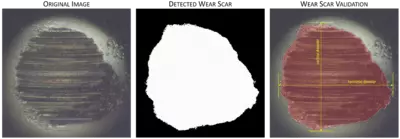

Automatic Scar Prediction

THE POWER OF ARTIFICIAL INTELLIGENCE (A.I.)

THE POWER OF ARTIFICIAL INTELLIGENCE (A.I.)

Every FBT-3 test is concluded by measuring the wear scar on the test specimens. It is the most manual aspect of any four ball testing and is prone to user errors and interpretation. Difficulty in visual observation of scars further increases the test variability.

With our proprietary automatic scar prediction software, you can now harness the power of Artificial Intelligence (A.I.) to automatically make consistent and precise wear scar measurements, overcoming the human error and greatly reducing the test variability.

- Determine extreme pressure (EP), wear preventive (WP), and frictional and fatigue behaviour of lubricants.

- Determine the incipient seizure and load wear index of lubricants.

- Benchmark the lubricants against the competitors in the market.

- Measure and compare the WP / EP of nanoparticles derived from carbon, metal oxide, sulphides, and nanocomposites.

- Compare the performance of lubricants at different loads, temperatures, base oils, additives, suppliers, etc.

- Compare and estimate the deterioration of lubricant quality by comparing fresh and used oil.

- Investigate the performance of polymeric materials in lubricants used to achieve better shear stability and minimize viscosity loss.

- Lubrication efficacy of biodegradable/vegetable oils compared to mineral/synthetic base oils.

DIGITAL IMAGE ACQUISITION SYSTEM (IAS)

DIGITAL IMAGE ACQUISITION SYSTEM (IAS)