Lubricity Tester DUCOM HFRR 4.2

THE NEXT GENERATION OF FUEL LUBRICITY TESTING HFRR 4.2

The Ducom High-Frequency Reciprocating Rig (HFRR) Lubricity Tester offers a range of features and benefits that make it an ideal choice for testing lubricity.

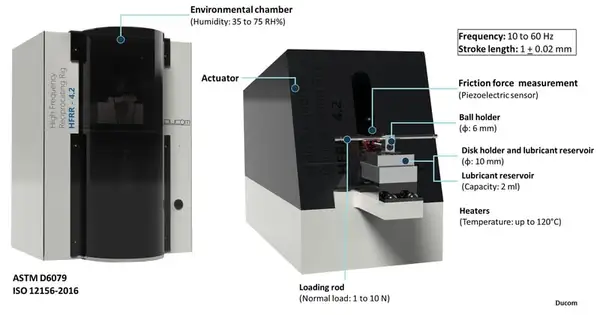

- HFRR unit in full compliance with ASTM D6079, ASTM D7688, ISO 12156-1, CEC F-06-A-96, IP 450/2000, SH/T 0765, GOST R ISO 12156-1-2006, JPI-5S-50-98

- Integrated salt-free high-precision humidity controller.

- Precise and consistent results: HFRR 4.2’s advanced design ensures measurements are accurate and repeatable.

- Easy to use: The tester is designed to be user-friendly, with intuitive controls and a clear display that makes it easy to operate.

- Versatile: The tester can test a wide range of oils and fuels, making it suitable for use in different industries.

- Efficient: The tester provides results quickly, allowing you to make informed decisions about your lubrication practices without delay.

- Durable: compact and robust structure ensures the stability and reliability of the test system.

- Modular design enables quick and easy replacement of components and accessories.

- A fully automated, user-friendly computer-controlled unit allows easy setup, data acquisition, analysis, and reporting of the test results.

Lubricity is the ability of a fluid to reduce friction and wear between two surfaces in relative motion. Lubricity is an important property of fuels, lubricants, and additives, as it affects the performance and durability of engines and machinery. Lubricity testing is a method of evaluating the lubricating quality of fluids under various conditions of pressure, temperature, speed, and load.

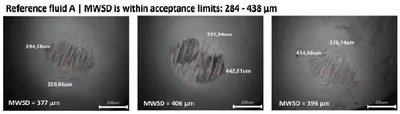

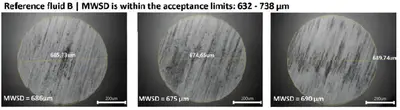

One of the most widely used lubricity testing methods is the High-Frequency Reciprocating Rig (HFRR) test, which simulates the sliding contact between a fuel injector and its bore in a diesel engine. The HFRR test measures the wear scar diameter (WSD) on a steel ball that reciprocates against a steel disk immersed in the test fluid. The WSD indicates the lubricity of the fluid, as a smaller WSD means less wear and better lubricity.

The Ducom HFRR 4.2 Lubricity tester is designed for excellent compliance with test standards and minimizes the cost of ownership. HFRR 4.2 has an integrated high-precision humidity controller that is salt-free and only needs distilled water to maintain precise humidity levels without influencing the temperature of the conditioned air. The system is computer-controlled and completely automated. It also has powerful and intuitive software that places all necessary controls on a single screen, allowing quick set-up of tests with minimal training.

The Ducom HFRR 4.2 Lubricity tester is designed for excellent compliance with test standards and minimizes the cost of ownership. HFRR 4.2 has an integrated high-precision humidity controller that is salt-free and only needs distilled water to maintain precise humidity levels without influencing the temperature of the conditioned air. The system is computer-controlled and completely automated. It also has powerful and intuitive software that places all necessary controls on a single screen, allowing quick set-up of tests with minimal training.

Ducom’s cutting-edge High-Frequency Reciprocating Rig (HFRR) Lubricity Tester provides accurate and consistent measurements of the lubricity of oils and fuels, making it an invaluable tool for various industries.

Ducom’s cutting-edge High-Frequency Reciprocating Rig (HFRR) Lubricity Tester provides accurate and consistent measurements of the lubricity of oils and fuels, making it an invaluable tool for various industries.

The DUCOM HFRR 4.2 features a high-precision servo motor that controls the reciprocating motion of the ball holder, a digital temperature controller that maintains the test fluid at a constant temperature, and a high-resolution optical microscope that measures the WSD on the ball and disk.

The ball moves back and forth at a high frequency, creating a wear scar on the specimen. The scar size is then measured and used to determine the lubricity of the sample.

HFRR-4.2 is a reliable and user-friendly device for measuring the lubricity of diesel fuels. It can perform tests according to various international standards, such as ASTM, ISO, DIN and others, by selecting the desired protocol from the software menu. This reduces the need for extensive user training, minimizes errors, and lowers operational costs.

- ASTM D6079: Standard Test Method for Evaluating Lubricity of Diesel Fuels by the High-Frequency Reciprocating Rig (HFRR).

- ASTM D7688: Standard Test Method for Evaluating Lubricity of Diesel Fuels by the High-Frequency Reciprocating Rig (HFRR) by Visual Observation.

- ISO 12156-1: Diesel fuel — Assessment of lubricity using the high-frequency reciprocating rig (HFRR). Part 1. Test method.

- GOST R ISO 12156-1-2006: Diesel fuel. Determination of lubricity by the HFRR-apparatus. Part 1. Test method.

- JPI-5S-50-98: Gas Oil – Testing Method for Lubricity.

- BS EN 590: Automotive Fuels – Diesel – Requirements and Test Methods.

- IP 450/2000: Diesel Fuel – Assessment of Lubricity Using the High-Frequency Reciprocating Rig (HFRR).

- CEC F-06-A-96: Measurement of Diesel Fuel Lubricity.

- SH/T 0765: Diesel fuel – Assessment of lubricity using the high-frequency reciprocating rig (HFRR).

The Specifications of Ducom Lubricity tester – HIGH FREQUENCY RECIPROCATING RIG

(HFRR 4.2)

- Frequency: 10 to 200 Hz

- Stroke: 20 µm to 2.0 mm

- Load: 0 to 1.0 kg (dead weight)

- Friction Force: 10.0 N (Max)

- Temperature: Ambient to 150 deg C (Ambient to 400 deg C is optional)

- Upper Specimen (Ball): 6.0 mm diameter

- Lower Specimen (Disk): 10.0 mm dia x 3 mm thick

- Power: 100 to 240 VAC, 50/60 Hz

Applications of Ducom Lubricity Tester HFRR 4.2

- Quality control of diesel fuels supplied by different refineries or supply chains.

- Detect the role of biofuels in diesel fuel lubricity.

- Synergistic effect of coatings and diesel fuel components in predicting the life of fuel pumps.

- Screening a range of viscosity modifiers and boundary additives to improve the insufficient lubricity of low Sulphur diesel.

- High-temperature lubricity behaviour of engine oils as a function of its base oil, anti-wear additives and viscosity modifiers.