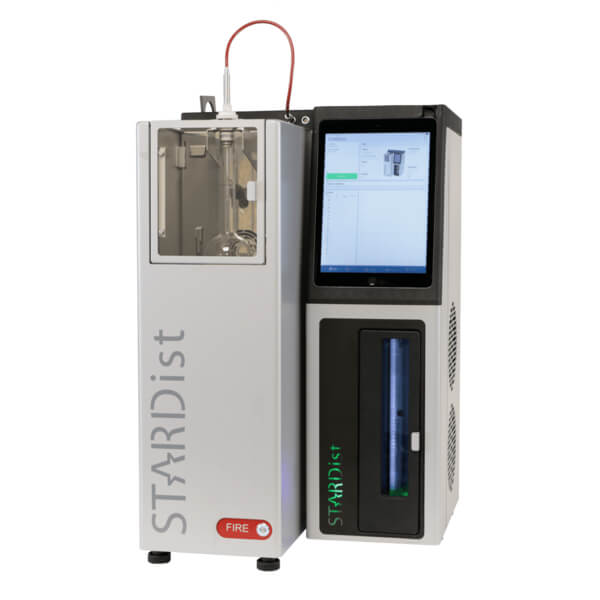

StarDist Automatic ASTM D86 Distillation analyzer

Automatic Distillation Unit StarDist

Orbis StarDist ASTM D86 distillation analyzer – Innovation in distillation testing

Method : ASTM D86, ASTM D1078, ASTM D850, DIN 51751, GOST 2177, IP 195, ISO 3405, JIS K2254

STARDist offers unique features such as Optical Dry Point testing, PreScan and fast heater cooling.

- User-Guided Start – for enforcing method compliance in preparation of sample and test

- PreScan – to measure actual Charge Volume and Sample Temperature measurement before test starts.

- Optical Dry Point – Dry point testing without a fragile, inaccurate and expensive probe.

- VOC Cold Trap – to minimize evaporated loss

- Method Validation – Real-time validation for method-specified limits.

- Auto Initial Heat –Fully Automatic & dynamic initial heat settings and heating regulation for unknown products

- Optimization – Automatic real-time optimization from Start to FBP

- Flask Installer Design – for always-correct height position of PT-100 probe relative to flask side-arm

- Automatic Lifts – for lifting heater and receiver into position & automatic lowering after test

- Easy To Use Software – for extensive customization

- Network Integration – for modern connectivity and data handling solutions

- UV fire sensor and built-in fire extinguisher

- Accurate volume detection

- Pre-programmed Group limits for automatic distillation programs

StarDist – Fully Automated Distillation

StarDist is designed for high performance Fully automated ASTM D86 distillation with Smart heater control algorithms and a user-friendly touch screen interface.

StarDist efficient heating control during different heating phases of the automatic distillation process from IBP to FBP ensures high accuracy and reproducibility, even for blends such as E15 or E20.

- Built-in function for automatic calculation of cetane index.

- Accurate temperature measurement and emulation of ASTM 7C/8C mercury thermometer

- Accurate control of condenser and receiver temperature.

- Accurate control of 4-5ml/min distillation rate

- Accurate control of heater during Initial Heating, IBP & FBP

- Pre-programmed Group limits for auto-programs

- Distillation test report includes residue, loss-corrected temperature results, custom points, etc.

- Data export in XML, JSON or PDF

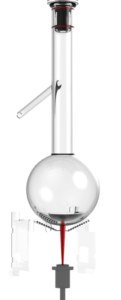

STARDist Optical Dry Point

StarDist Optical Dry point sensor is an ideal solution to avoid incorrect positioning of conventional sensors which will lead to inaccurate dry point detection.

No more expensive fragile dry point sensors

Pre Scan

StarDist automatic ASTM D86 distillation offers Pre Scan function that significantly increases the reproducibility of results.

Pre Scan measures both the volume and the temperature of the sample before each test.

The volume will be normalized to 100%, and the temperature will be the set point for the receiving chamber temperature during the test. The same “start” temperature as the “recovery” temperature avoids temperature-induced volume expansion/shrinkage. which affects the distillation accuracy.

Stardist ASTM D86 Distillation analyzer Specifications

| Methods | ASTM D86, D1078, D850, E123, IP195, DIN51751, ISO 3405, GOST 2177, JIS K2254. |

| User interface | iPad with STARDist app software. Available in App Store. App & updates are free of charge. |

| Heating control | Smart multiparameter-based algorithm calculates and applies the required heater settings for IBP, FBP and (4-5 ml p/min.) speed control in real-time. Suitable for unknown samples and/or complicated blends such as E20. Speed control range: 2-11 ml p/min. |

| Heating system | Low mass/low voltage heater. 2 user adjustable fans for extra fast cooling after test. Automatic heater lift with correct flask pressure & positioning. Automatic shut-off in case of fire. |

| Condenser cooling | Solid state: based on Peltier elements with heat-pipe assisted heat sinks and silent fans for heat dissipation. No liquids involved. Condenser temperature can be increased during the distillation to deal with “light start / heavy end” products to prevent both evaporation loss and product waxing in the condenser tube. Temperature range: 0 – 65°C. Resolution 0.1°C. |

| Volume detection | Smart HD CCD camera for accurate volume measurement. Detects actual bottom of meniscus. Suitable for “smoke producing” products. Automatic calibration of the camera against cylinder. Resolution: 0.01 ml, accuracy: 0.01 ml, charge volume: 0-105%. |

| Receiving chamber | Built-in drop deflector. Cooling: similar to condenser cooling. 1 sensor for receiver chamber temperature and 1 sensor for sample temperature. Automatic lift moves receiver cylinder up to be sealed at the top, where a small hole ensures exposure to atmospheric pressure. Then; a tube laid along the condenser tube acts as “VOC Cold Trap”, preventing vapors from escaping the receiver (loss).Temperature range: 0 – 45°C. Resolution 0.1°C. |

| Residue & Loss | Various options for residue measurement: automatic prediction, camera measurement, manual measurement and preset value. Loss correction is automatically applied to temperature readings. |

| Vapor temperature measurement | PT-100 class A probe with 10-point calibration data storage and automatic probe ID detection. Calibration certificate standard supplied. True dynamic simulation of ASTM 7 & 8 in-glass thermometer behavior (lag time and emergent stem). Range: 0 – 450°C ASTM / 0 – 500°C absolute. Units: ºC, ºF. |

| Dry point detection | Optical Dry Point: IR sensor for automatic dry point detection. No dry point probe required. (Conventional dp probe still available) |

| Pressure | Built-in pressure sensor. Automatic correction of temperature results to atmospheric pressure. Range: 70 to 110 kPa, res. 0.1 kPa. |

| Cetane index | Built-in function for automatic calculation of cetane index. |

| Fire safety | UV sensor for fire detection. Built-in fire extinguisher. N or CO2 supply required from lab (connection hose is supplied). |

| System Health | Automatic quick system health check before every distillation run to ensure all components are in excellent state. |

| Connectivity | 1 x RJ45 (LAN) for connection to LIMS, Windows PC, FTP server, Kiosk printer and/or connection between multiple STARDist units. |

| Dimensions | Dimensions: 40cm x 40cm x 63cm (WxDxH), weight: 40 kg |

| Accessories | Kiosk printer |

| Voltage | 100-240 VAC 50/60 Hz |

| Power | 1200 W |

| Lab conditions | Environment temperature 10°C – 30°C. Environment humidity up to 80 % at 30°C. |