Combination Octane Rating Unit

Koehler Octane Rating Unit Engine K90901

Methods: ASTM D2699, ASTM D2700; ISO 5163, ISO 5164, IP 236, IP 237

- Combination Octane rating unit with easy conversion between MON and RON methods in under 15 minutes with no need to change the flywheel

- The dual-speed motor with slide base steadily provides constant octane engine speeds as per ASTM D2699 and ASTM D2700 methods during operation

- Durable engine crankcase with high strength and rigidity for various fuel types to ensure long service life and carefree operation

- The engine’s cylinder assembly allows the compression ratio to be altered by adjusting its height using the electric motor assembly.

- The dial indicator is installed on the octane engine for direct reference to the cylinder height

- The compression ratio and ignition timing are displayed directly on the operating panel. It also displays barometric pressure compensated

- With digital knock signal adjustment, combustion knock is converted into a stable and accurate analog signal to improve accuracy and efficiency

- The Octane rating tester engine automatically stops when its safety system detects faults.

- The Octane engine eliminates resonance pulses and back pressure for more consistent and accurate results using the exhaust surge tank system.

- The intake air humidity equipment controls the moisture content of the intake air per the ASTM specifications without changing moisture grains daily.

The K90901 Standard Model Combination Octane Rating Unit is the latest model of octane engines with many easy-to-use features including automatic functions and enhanced documentation capabilities, conforming to the latest ASTM D2699 (RON) and ASTM D2700 (MON) test methods.

The parameters can be adjusted according to the ASTM D2699 and D2700 specifications through the Octane engine’s operating panel. The professional and clear design of the operating area makes the octane rating operation convenient and the data is easy to read and record. The auto-setting function of the octane engine effectively simplifies operational procedures and improves the efficiency of octane testing. The operating panel has a protection system and push-button to avoid improper operation.

Since the inception of octane ratings in 1928, fuel formulations have undergone significant evolution to enhance anti-knock capabilities. Early fuels, prone to knock, necessitated lower compression ratios to prevent engine damage.

The development of catalytic cracking and anti-knock additives revolutionized fuel formulations, reducing susceptibility to knock and enabling higher compression ratios. Tetraethyl lead, a popular anti-knock additive, eventually gave way to safer alternatives like ethanol, which not only boosts octane ratings but also promotes cleaner combustion.

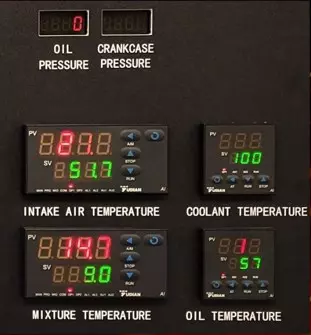

Digital Monitoring

Digital monitoring for: Engine Speed (RPM), Time Counter (Hr), Timing Angle (Deg.), and CR Digital Counters

Temperature Control

Digital control and monitoring of Intake Air Temperature, Coolant Temperature, Air Mixture Temperature, Oil Temperature, Oil Pressure, and Crankcase Pressure.

Conversion from RON to MON occurs in a matter of minutes. No flywheel or timing adjustments are needed. Change the 4 jets and the unit is ready to run.

Built-in Fault Indicators to diagnose issues. Emergency Stop button on the front face of the unit.

Koehler K90901 Combination Octane Rating Unit Engine – Technical Specifications

| Conforms to: ASTM D2699, ASTM D2700; ISO 5163, ISO 5164, IP 236, IP 237 |

| Working Range: 40 to 120 Octane Number |

| Operation Conditions: |

| Cylinder Jacket Coolant Temperature: 100 °C ± 1.5 °C |

| Crankcase Oil Temperature: 57 °C ± 8.5 °C |

| MON Conditions: |

| Engine Speed: 900 ± 9 rpm |

| Ignition Timing: Variable as cylinder height is changed |

| Intake Air Temperature: 38 °C ± 1 °C |

| Intake Mixture Temperature: 149 °C ± 1 °C |

| RON Conditions: |

| Engine Speed: 600 ± 6 rpm |

| Ignition Timing: 13° BTDC |

| Intake Air Temperature: 52 °C ± 1 °C |

| Engine Information: |

| Compression Ratio (C.R.): 4:1 – 18:1 |

| Cylinder Bore (diameter): 82.55 mm |

| Stroke: 114.30 mm |

| Carburetor Venturi (Research): 14.30 mm |

| Intake Valve Clearance (Hot): 0.20 mm ± 0.025 mm |

| Exhaust Valve Clearance: 0.20 mm ± 0.025 mm |

| Intake Valve Opens Timing: 10° ± 2.5° ATDC |

| Intake Valve Closes Timing: 34° ABDC |

| Exhaust Valve Opens Timing: 40° BBDC |

| Exhaust Valve Closes Timing: 15° ± 2.5° ATDC |

| Crankcase Oil Pressure: 172 kPa – 207 kPa (25 psi to 30 psi) |

| Dimensions |

| lxwxh,in.(cm): 68x42x58 (172.72×106.68×147.32) |

| Net Weight: 2250 lbs (1022 kg) |