Automated Air Release Value Analyzer

Air Release Properties of Petroleum Oils K88539

Methods : ASTM D3427; IP 313; ISO 9120; DIN 51381; NF E 48-614; NF T 60-149; BS 2000 Part 313

Koehler Air Release Value Analyzer is designed to determine automatically the air release properties of hydrocarbon-based oils following ASTM, IP, and other methods.

- Integrated Touch Screen Control Panel

- Automatic Lift System that moves test vessel from air source to balance sinker

- Automatic calculation of final sample density for determination of air release value.

- Integrated Circulation Bath with water level indicator

- Integrated Balance

- Secure the Clamp Mechanism of the air tube

- Automated Jacketed Test Vessel draining

- Safety Shield

- LIMS Compatibility

The lubricating efficiency of Lubricants and Oils can be shortened by an excess amount of entrained air and can cause disruptions in operating equipment.

The time taken for hydraulic fluids and lubricating oils to release entrained air and gases can be determined by Air Release Value test.

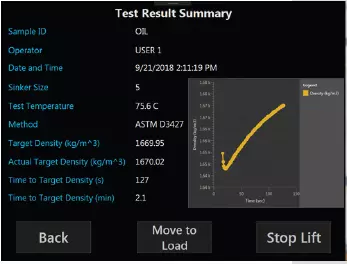

The Koehler Automated Air Release Value Analyzer consists of a test vessel and airflow control equipment for delivering heated air at the specified flow rate to a lubricating oil sample maintained at a constant temperature. The Integrated Touch Screen Control Panel guides the user from start to finish of the test operation and provides density calculation and timing operation for measuring the air release value of the test sample. Drying oven available as an additional accessory for warming test oil at temperatures of up to 100°C; Integrated Circulating Bath and air bath for sinker; compressed air heater, over-temperature and over-pressure protection circuitry. Automatically measures the time for air release.

The ability of a turbine, hydraulic, or lubricating oil to separate entrained air is a key performance characteristic in applications where agitation causes a dispersion of air bubbles in the oil. To determine air release properties, the sample is heated to a specified test temperature and blown with compressed air. After the airflow is stopped, the time required for the air entrained in the oil to reduce in volume to 0.2% is the air bubble separation time.

Supplied with

- Sinkers, 5mL and 10mL

- Integrated Balance

- Integrated Circulator

- Air Bath for Sinker

- Tubing and Fittings

- Platinum Wire

- Jacketed Test Vessel

| Conforms to the Specifications of: | ASTM D3427; IP 313; ISO 9120; DIN 51381; NF E 48-614; NF T 60-149; BS 2000 Part 313 |

| Part No K88539 | Automated Air Release Value Analyzer, 220-240V 50/60 Hz |

| Temperature Range | Ambient to 75 °C (167 °F) |

| Sample Temperature Stability | ± 0.1 C |

| Air Temperature Stability | ± 0.2 C |

| Density | ± 0.001 g/ml |

| Electrical Requirements: | 230V, 50/60Hz, Single Phase |

| dimensions W x D x H, cm | 60.96×58.42×86.36 |

| Net Weight | 53 Kg |

| Accessories | |

| K885-240-1 | Convection Oven, 230V |

The Koehler Automated Air Release analyzer can be used for many applications like

Research and development: Automated Air Release Value analyzer can use for research and development of new turbine, hydraulic, or lubricating oil designs and technologies. The results can help to improve the performance and reliability of fluids in a wide range of applications.

Quality control: The Automated Air Release Value analyzer can be used to verify that new turbine, hydraulic, or lubricating oil meets quality control standards. This will help to ensure that oils are functioning properly and prevent air bubbles from entering the system.