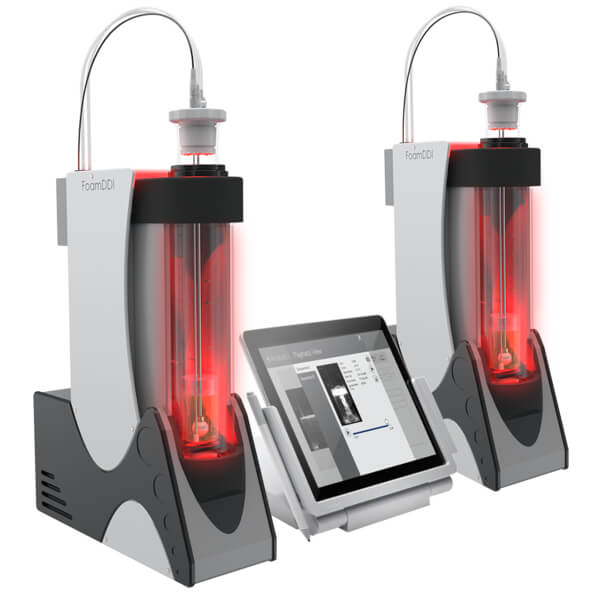

FoamDDI – Automated ASTM D892 and D6082 foam test unit

Foam Digital Detection Imaging FoamDDI

At last, full automation for your Foam Testing.

Fully automated ASTM D892 and D6082 foam test units.

Methods: BS 2000 Part 156, ASTM D892, ASTM D6082, FTM 791-3211, IP 146, ISO 6247

- Fully unattended operation

- Small footprint with integrated heating and cooling

- Automatic Detection of proper fill volume

- Graphing of FOAM and Temperature

- Ability to measure both Static and Dynamic Bubbles

- Long-Lasting LED Light Source

- Integrated temperature sensor.

- Integrated Mass Flow Totalizer for exit air

- Built-in totalizer

FoamDDI automatic D892 and D6082 foam test unit accurately controls the airflow, temperature and sequence, which is then augmented using a unique VISION algorithm to accurately determine the height of static and dynamic foam heights, improving the precision and accuracy of ASTM D892.

Full automation of D892 and D6082 foam test and Elimination of User Bias.

Contamination in the form of air which can be foam or the entrained air bubbles creates adverse effects in machinery and lubricants. Issues such as incomplete oil films, low oil pressures, accelerated oil degradation, and additive depletion are symptoms of high foam tendency, which can produce metal wear, inadequate lubrication, cavitation in pumping, and mechanical failures.

Standard Test Method ASTM D892 was developed for lubrication testing and to determine the foaming characteristics of lubricant oils by empirically rating their foaming tendency and stability. Standard Test Method ASTM D892 was developed to determine a lubricant’s ability to resist foam formation and dissipate foam creation. However, measuring foam heights is a challenge, as it relies on the human eye” to measure foam heights which creates a significant user resulting in human errors, bias, and poor repeatability and reproducibility. The FOAM Digital Detection Imaging (FoamDDI) accurately controls the airflow, temperature, and sequence, which is then augmented using a unique VISION algorithm to accurately determine the height of the station and dynamic foam heights, while greatly improving the precision and accuracy.

Principle:

The all-new FoamDDI eliminates the need for sample manipulation and critical timing involved with regular foam detector methods. Using a patent-pending heating and cooling system with a vision algorithm and lubrication testing automation the FoamDDI, records, calculates, and displays accurate results with little to no operation bias. Determinations come from this foam detector in minutes!

- Using a high-resolution camera with state-of-the-art optics for lubrication testing, FoamDDI quickly brings a sample in the inserted cylinder to test temperature.

- After a soaking time, the foam detector and analyzer start air for FOAM production.

- Air Flow is controlled using Mass Air Flow Controllers (MFC)

- At the 5 min. mark, an LED light source is activated.

- VISION algorithm is activated and begins analyzes

- The complete sequence is recorded and analyzed.

- The test is completed or if desired, the next sequence can automatically continue.

| Applicable Test Methods | ASTM D892, IP 146, BS 2000 Part 156, FTM 791 3211, ISO 6247 |

| Sequence | 1, 2, & 3 |

| Display Units | mL of FOAM, Video, and Time |

| Detection Method | Digital Video Detection |

| Precision | +/- 0.25% of Raw Reading |

| Detection Method | Patent Pending Digital Detection |

| Measuring Time | Method and Sequence Dependent (Typically <1 hr.) |

| Calibration | Vision Calibration with Standard |

| Display | 10.1” Projective Capacitance Touch |

| Interfaces | Ethernet x2, USB 3.0 x1, USB 2.0 x4, HDMI, VGA, USB Printer, USB Mouse, Keyboard |

| Memory / Storage | 64 GB SSD Storage |

| Humidity | Up to 75% Non Condensing |

| Temperature Range | 20° to 100° C |

| Power | Auto-switching 90 ~ 264VAC, 47 ~ 63Hz, 280 Watt Power Supply |

| Space Requirements | 80 mm (3”) on Sides and Back |

| Weight | 10 Kg. (22 lbs.) |

| Dimension | 350x300x270mm (14x12x11”) |

| Gross Dimensions & Weight | 400x350x530mm, 15Kg. (15x14x21” 24lbs) |

Automation of ASTN D 892 and D 6082 Foam testing.