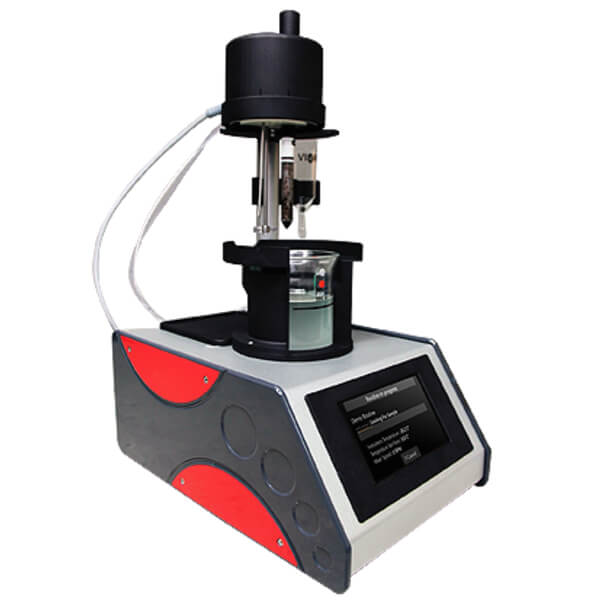

Visaya – Automated NACE Apparatus (ANA)

Fully Automated Rust Apparatus ANA

Methods: ASTM D665, ASTM D7548, NACE TM-01-72

Save your Time by Using the Fully Automated NACE apparatus to Determine the Corrosive Properties of Petroleum products.

Automate your sequencing process for your liquid hydrocarbon products

The ANA (Automated NACE Apparatus) is a fully automated single position test apparatus to determine the corrosive properties of petroleum products and other liquid hydrocarbon products that are not water-soluble for storage, transport through a steel pipeline or rail tanks.

- ASTM Complaint

- Easy-to-Use Touch Screen interface with 1-2-3 Button Operation

- Digital Image Logging Complete with Operator Notes and Calculated Results

- Integrated Computer for Easy Interface with Direct LIMS Connectivity, USB, Ethernet and HDMI Outputs

- Removes Inherent Bias with Visual Rating

- Voltage and Current Controlled Light Box for Consistent Ambient Light Environment

- Automatic Detection of Iron Specimen Size

- Long-lasting LED Light Source

- Auto Rotation of Specimen for full 360º Recording

- Enables Single-Hand Loading via Two Part Holder and Clip

- Eliminates Fingerprints and Unwanted Markings on Spindles Strips

- Specimen Holder Doubles in Functionality as Tool for Manual Verification

- Prompts Operator When Iron Rods Shrink to Unusable Sizes

- Provides Auto Recognition of Proper Dimensions

The ANA saves you time by automating the sequencing process. This instrument features an embedded industrial-grade programmable logic controller (PLC) with easy-to-use software, LCD Screen and simple single button control for all functions.

Sensors used in modern automotive fuel systems often have iron or ferrous alloys, which may be susceptible to corrosion from sulphur and other hetero compounds present in gasoline.

In the past decade, refiners have shifted to producing lower-sulphur gasoline. This process requires more severe hydro-treating that destroys naturally occurring compounds that give some protection against sulphur-based corrosion. Ensuring that fuel stays within acceptable corrosion limits require constant and accurate testing.

Operation of ANA – Automated NACE apparatus is simple and involves 6 steps.

Step 1: Insert baffle beaker with 300mL sample

Step 2: Load Polished Cylindrical Steel Specimen onto the holder

Step 3: Load 30mL of water into a reservoir at the top

Step 4: Lower test head down onto the beaker

Step 5: Select the test method (D665), and press Start

After reaching a programmed setpoint temperature

ANA will automatically lower the Specimen into the beaker

After 30 minutes, water will be dispensed.

The test will continue to run for 3.5 hrs. of exposure

After the prescribed time, ANA will automatically raise the Specimen to halt exposure

ANA will alert the operator to retrieve the specimen for rating

Step 6: Specimen can be rated manually or with FeDDI Analyzer

Test Temperature : 30° to 100° C

Display Units: Time (HH:MM: SS) & Degrees ° C, RPM

Speed: 10 to 1,000 RPM

Measuring Time: Configurable, Typical 3.5 Hrs.

Liquid Volume: 5 to 40 mL

Calibration: Factory Supplied Calibration | Temperature, Speed and Time

Display: Touch Screen

Interface: Ethernet for Communication and Firmware Upgrade

Power : Auto-switching 90~264VAC, 47~63Hz, 280 Watt Power Supply

Dimension : 20”H x 8”W x 16”D

Weight: 6Kg

Shipping Dimensions & Weight : 16”H x 16”W x 16”D, 7.7Kg

Humidity: < 85% non-condensing

Applications of NACE Apparatus ANA

ASTM D665: Standard Test Method for Rust-Preventing Characteristics of Inhibited Mineral Oil in the Presence of Water

ASTM D7548: Standard Test Method for Determination of Accelerated Iron Corrosion in Petroleum Products

NACE TM0172: Determining Corrosive Properties of Insoluble Petroleum Product Pipeline Cargoes