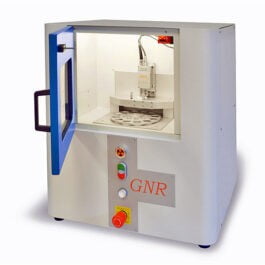

Benchtop Retained Austenite Analyzer- Arex-D

First Benchtop Retained Austenite Analyzer AreX D

AreX D is the first Benchtop Retained Austenite analyzer designed for the analysis of steel.

- Compliance with ASTM E 975-03 standard practice

- High accuracy.

- The standard deviation is better than 0.6%.

- Limit of detection 0.5% of RA.

- Fast measurement – 3 min max

- Easy to use One button operation. No specific XRD information required.

- No Sample preparation required.

- Custom solutions available depending on the application.

- Most suitable solution for QA and QC control in production line

- Durable instrument – No moving parts.

- Built in Video camera for easy and precise sample positioning

AreX D the first desktop X-Ray diffractometer designed in compliance with ASTM E 975-03 for fast, accurate and easy determination of Retained Austenite in steel with near random crystallographic orientation.

Mechanical and physical properties of steels depend on phase composition. Phase transformation in critical and structural steel component is sensitive and important parameter to be evaluated.

Extremely low concentration and accurate determination of Retained Austenite is required in industrial processes. Traditional metallographic investigation like chemical etching and optical determination of Retained Austenite are often ineffective due to the low accuracy and sensitivity of method.

Accurate measurements of retained austenite is essential during the set up and control of many heat treatment processes as well as in Additive Manufacturing processes.

X-Ray Diffraction (XRD) is considered the most accurate method available that can determine retained austenite levels down to 0.5%.

AreX D is a fixed angular range X-Ray Diffractometer designed for quantitative determination of Retained Austenite. Easy to use high precision Arex D safe and easy to use.

The integrated intensities of the austenite (220 and 311) and the ferrite (200 and 211) diffraction peaks are measured on the AREX diffractometer. The use of multiple diffraction peaks minimizes the effects of preferred orientation and allows interference from carbides to be detected.

AreX D is the unique benchtop retained austenite analyzer able to guarantee compliancy with the ASTM E 975 – 03.

- Air Cooled X-Ray Tube

- Micro Focus Mo Anode X-Ray Source

- Zr Filter

- Angular Range 21.5° – 44.5° 2Theta

- Linear Silicon Strip Detector (Dectris Mythen 1D 450)

- Video Camera for easy and precise sample alignment

- Door interlock switch, thick steel frame and lead shield for x-ray safety protection

- X ray safety compliant with ANSI N43.3-1993

- Power Supply: 110/220 V 50/60 Hz

- Power 50 W

- Dimension: 490w x 550d x 360h mm

- Sample Holder Dimension: 200w x 150d x 70h mm

- Weight: 37 kg.

Acquisition and Analytical SW: Austenite

Microsoft Windows program designed for the control of the AreX Diffractometric System.

Automatic Retained Austenite quantification conform to ASTM E 975-03 Standard Practice.

Display, printout and disk storage of results.

- Bearing and Gear Industries

- Heat Treatments plants

- Automotive industries (gear boxes, transmission)

- Material and Failure analysis Laboratories